Addressing Today's Challenges In Commercial Buildings

Intro

In recent years, the motivations for carbon footprint reduction together with increased energy prices resulted in greater interest in smart buildings solutions. According to various sources, the smart building market will more than double between 2018 and 2026. Being in the mid-point of this time interval, let’s try to address some of the challenges regarding the effective operation of HVAC systems in modern office buildings.

Challenges

Together with lights, HVAC (Heating, Ventilation and Air Conditioning) systems represent the biggest energy consumers in the operation of office buildings. Modern buildings are designed to allow high efficiency operation and to pass new standards and requirements. However, even the most efficient systems will not operate efficiently if not properly setup and maintained.

We believe that utilizing machine learning techniques in Building Analytics software brings additional value for the customers. Here are some examples:

1. Control inefficiencies

Even a modern hybrid car can have high fuel consumption if the driver doesn’t operate it properly. The same applies to building HVAC systems.

Some BMS (Building Management Systems) manufacturers offer data analytics as a service: a dedicated expert team acquires and analyzes seasonal data on a regular basis and provides recommendations, for example setpoints adjustments. We believe that this can be done automatically. We propose the following 3-step approach:

- Detection of control inefficiency with potential energy saving (e.g. if there is simultaneous heating and cooling without the need for dehumidification)

- Automated creation of summary report including specific action recommendation. Potential savings can be monetized and included in the report. This makes it more attractive for the owner of the building, with clearly visible added value.

- Once the Building Analytics software is integrated with BMS, setpoints can be calculated online utilizing machine learning and optimization methods. The adjustment of setpoints is done automatically to provide immediate savings.

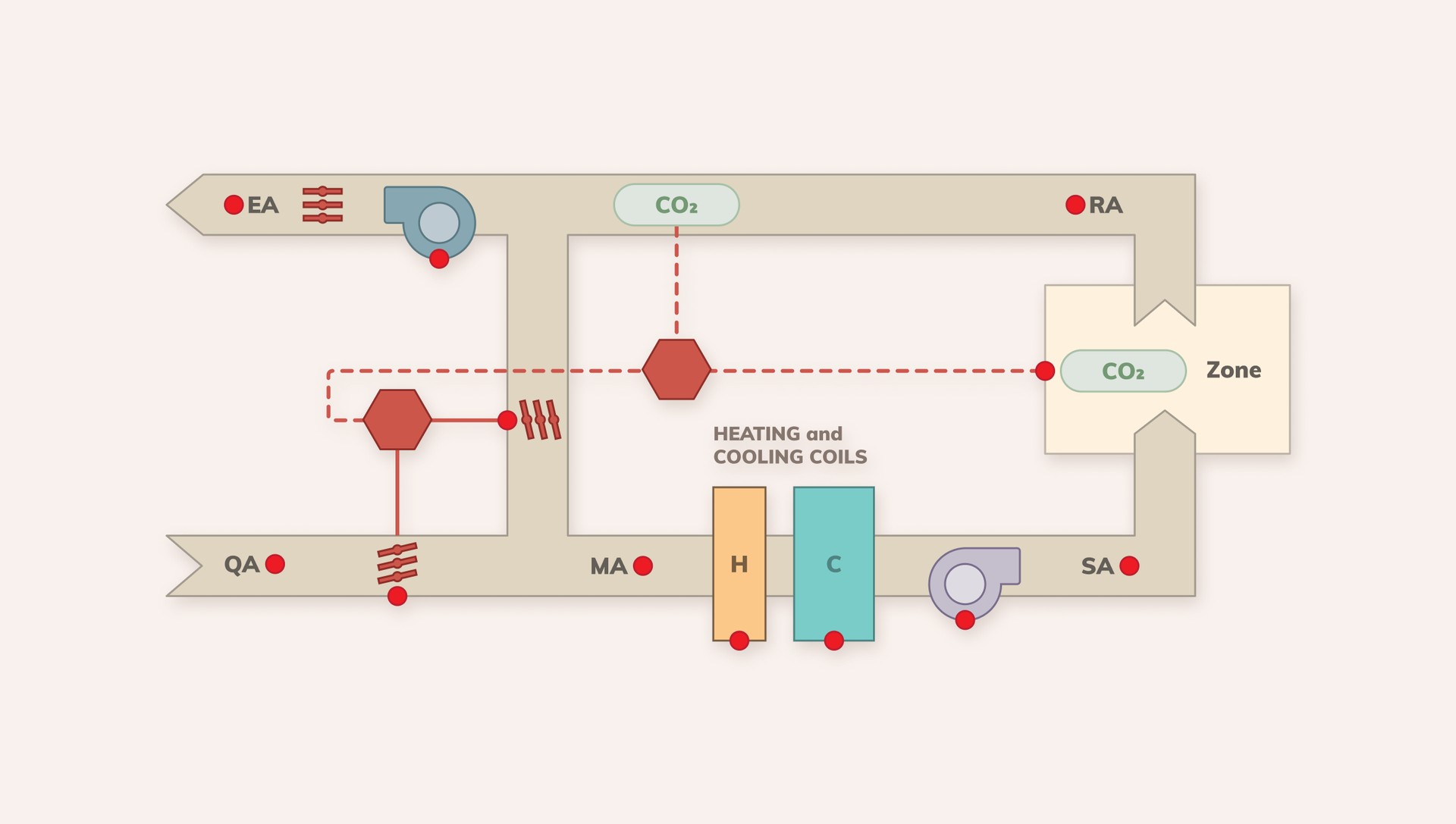

Faulty sensor readings also lead to inappropriate control strategy. Therefore a reliable detection of frozen or out-of-range sensors results in system operation savings. The figure below illustrates a typical air handling unit scheme including sensor locations represented by red dots.

Air Handler unit scheme (EA – exhaust air, MA – mixed air, RA – return air, OA – outdoor air, SA – supply air)

2. AFDD

For years the building industry has continued towards the introduction of an automated fault detection and diagnostics technology to enable predictive maintenance strategies. This was primarily given by the fact that the deterioration of equipment causes higher energy consumption and increased costs. In today’s world, facility teams need to have remote visibility into building performance combined with automated root cause analysis of equipment issues. No one wants to send technicians on to the site unless they must. Moreover, with automated diagnostics (the second “D” in “AFDD”), service technicians can come to the site already equipped with all necessary tools and service parts - this again saves time and costs of the service. According to the US Department of Energy’s Operations & Maintenance Best Practices Guide, reduction in maintenance costs can be up to 30%. Application of AFDD strategy enables the owners of the buildings to do as much as possible without the need to enter the building.

How does it work?

The AFDD system typically comprises of the set of the rules defined by the subject manner experts (i.e. expert system). An advantage of such approach is good expandability, the limitation on the other side is less flexibility. With different types of equipment and buildings, the expert system becomes more complex.

An alternative approach is to identify and build equipment performance models based on historical data. The model continuously calculates and monitors the value of selected a performance indicator and when it reaches the pre-defined threshold, an event (e.g. alarm, log, report) is triggered. Because the model is data-driven (and not physics based), the model parameter values are derived from historical data which needs to be collected ahead in sufficient quantity and quality.

Both approaches can be combined. The main idea remains the same – to make the important switch from being reactive to become proactive.

3. Indoor Air Quality

The pandemic has brought a new focus on the topic of indoor air quality. As we know, the SARS-CoV-2 virus mainly spreads via respiratory droplets, released when a person coughs or sneezes. The duration for which a virus can survive on a surface depends on multiple factors, such as surface type and environment, including air temperature and humidity. General guidance for HVAC systems is the introduction of high-quality filters and increased outdoor air ventilation. It becomes important to find the right balance between the desired comfort of the environment (i.e. temperature and humidity levels) and the strategies to mitigate the spreading of the virus in the office space.

You need to understand how your HVAC system is performing if you want to proactively manage, not just monitor, IAQ. For example, it is important to detect early on that the office room is not receiving the required ventilation levels together with the root-cause reasoning. This information is provided by the AFDD system in place.

IAQ improvement is a subject of ongoing research because the building owners will need to leverage tools to recover confidence in returning to the workplace safely.

Conclusions

As presented, the application of advanced analytics and machine learning in Building Analytics software brings clear benefits for the owners of the building with high return of investments as well as increased satisfaction of the tenants. Proper software design is required to ensure the scalability of the solution. Domain expertise plays an important role in the algorithm selection and collected data quality and quantity is essential during model design and validation process.

The only remaining questions is: are you ready for the transition from reactive maintenance to proactive maintenance? We are ready to help you.